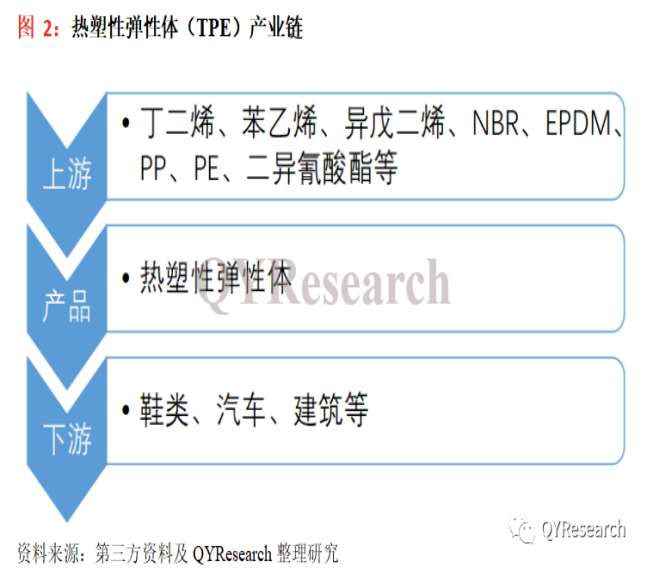

Introduction to TPE Industry Chain

[Upstream situation] Raw materials of thermoplastic elastomer (TPE) include butadiene, styrene, isoprene, NBR, EPDM, PP, PE, diisocyanate, etc. Styrene is produced through the synthesis and dehydrogenation of ethylene and pure benzene. Butadiene and isoprene are mainly produced by the extraction of C4 and C5 fractions, which are by-products of ethylene plants. The supply and price fluctuation of ethylene are greatly affected by the fluctuation of international crude oil prices and downstream market demand, which further affects the supply fluctuation of main raw materials used in TPE products, The price of main raw materials used in TPE product production fluctuates greatly.

[Thermoplastic Elastomer (TPE) Industry] In recent years, with the increasing demand of the thermoplastic elastomer market, more and more enterprises have entered the thermoplastic elastomer industry. Globally, the technology of foreign developed countries is relatively mature. Multinational companies such as Kraton Polymers, Dynasol, Mitsubishi, LG Chemical, etc. dominate the global high-end thermoplastic elastomer product market. In China, due to the late start, there is a gap between the key technologies of high-end thermoplastic elastomer products and those of foreign developed countries. However, with the increasing investment in research and development and the continuous breakthroughs in independent innovation technologies in China, there is also a certain development foundation in the field of thermoplastic elastomer, and there is a large market growth space. In addition, more and more enterprises join in the independent R&D and production of thermoplastic elastomer.

[Downstream situation] The market demand for thermoplastic elastomers continues to increase, mainly in the following three aspects: First, bio based recycled plastics can promote the development of green economy in the whole industry. As an important green material, thermoplastic elastomers have begun to take shape in the market; Second, for a long time, the market impact of the plastic processing industry has been relatively serious, and it is urgent to strengthen the industrial innovation. Thermoplastic elastomers can alleviate the market pressure to a certain extent, which has been highly valued by the industry; Third, automobile manufacturing, aviation, civil construction, electromechanical, transportation, medical care, agriculture, etc. are the ultimate application fields of thermoplastic elastomer. With the rapid development of these fields, the market demand for thermoplastic elastomer is also increasing.